Leading countries of cabinets for electric sockets from China

Leading countries of cabinets for electric sockets from China

China is a world leader in the production of electrical products, and cabinets for electric sockets are no exception. Millions of such products are sent around the world annually, providing the needs of various markets - from small private houses to large industrial enterprises. But where do materials and components for these cabinets come from? Let's look at the leading countries that supply raw materials and components for Chinese production.

1. Dominative metal suppliers:

Most cabinets are made of metal, most often steel or aluminum. Here are the leaders of countries with a developed metallurgical industry. Australia, Brazil and South Africa are large suppliers of iron ore, which is later processed into steel. For aluminum, the key partners of China are countries with rich bauxite deposits, for example, Australia and Guinea. The quality and price of metals play a decisive role in the cost of the final product, and therefore the choice of suppliers is a strategically important issue for Chinese manufacturers.

2. Key suppliers of plastic and electronics:

The plastic used in the production of cabinets can be imported from various countries specializing in the oil refining and production of polymers. Here the geographical scatter is wider: from the Middle Eastern countries to the countries of Southeast Asia. As for the electronic components - switches, outlets and other elements - China often cooperates with companies from South Korea, Japan, as well as Taiwan, which are known for its advanced electronics. This cooperation provides high quality and functionality of finished products.

3. The influence of global supply chains:

The production of cabinets for electric sockets is a vivid example of a complex global supply chain. China acts as a central node that collect components from around the world and sends finished products to the global market. This is mutually beneficial cooperation, where each country specializes at a certain stage of production, which allows you to optimize costs and ensure the competitiveness of products. However, any fluctuations in the world market - from raw materials to geopolitical factors - can affect the stability and effectiveness of the entire supply chain.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

High voltage distribution cabinet HXGN15-12

High voltage distribution cabinet HXGN15-12 -

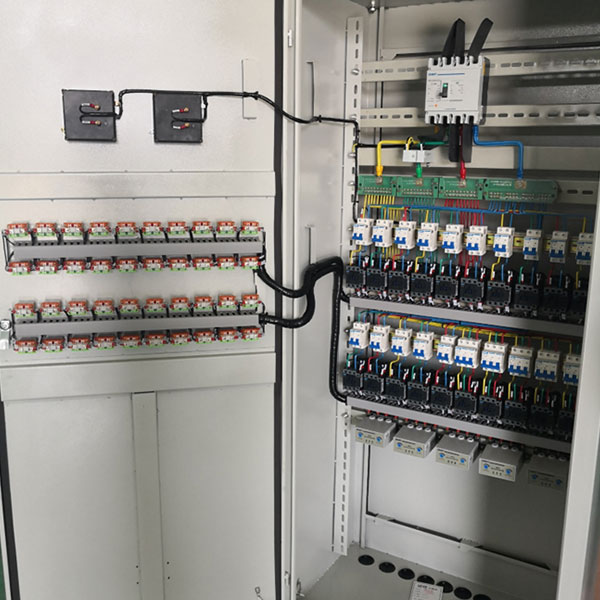

Complete low -voltage equipment JXF

Complete low -voltage equipment JXF -

Power transformer S13

Power transformer S13 -

GGD stationary cabinet 1600-4000A

GGD stationary cabinet 1600-4000A -

GKG-12 high voltage

GKG-12 high voltage -

High voltage distribution cabinet KYN61-40.5

High voltage distribution cabinet KYN61-40.5 -

High voltage cable branch box

High voltage cable branch box -

Complete low -voltage equipment GKK

Complete low -voltage equipment GKK -

Complete low-voltage equipment XL-21

Complete low-voltage equipment XL-21 -

High voltage distribution cabinet KYN28-12

High voltage distribution cabinet KYN28-12 -

Complete low-voltage equipment MNS 4000-6300A

Complete low-voltage equipment MNS 4000-6300A -

Inflatable annular network cabinet

Inflatable annular network cabinet

Connectedsearch

Related search- Cable tray fasteners in China

- Cheap manufacturers of external distribution devices

- Prices for external installation distribution devices in China

- Prices for camera chambers in China

- Distribution boards production plants 54 in China

- Cable tray 200

- Prices for low -voltage MNS distribution devices in China

- Prices for installations of substations in China

- Buy a camshaft

- Leading Chinese buyers of bridge frames