Products

-

GKD low voltage

-

High voltage distribution cabinet HXGN15-12

-

Combined substation ZBW-12 (American box transformer)

-

Opening and closing external intelligent station

-

Complete low -voltage equipment GCS

-

GGD stationary cabinet 600-1500A

-

Complete low-voltage equipment MNS 800-2500A

-

High voltage distribution cabinet KYN61-40.5

-

Complete low-voltage equipment XL-21

-

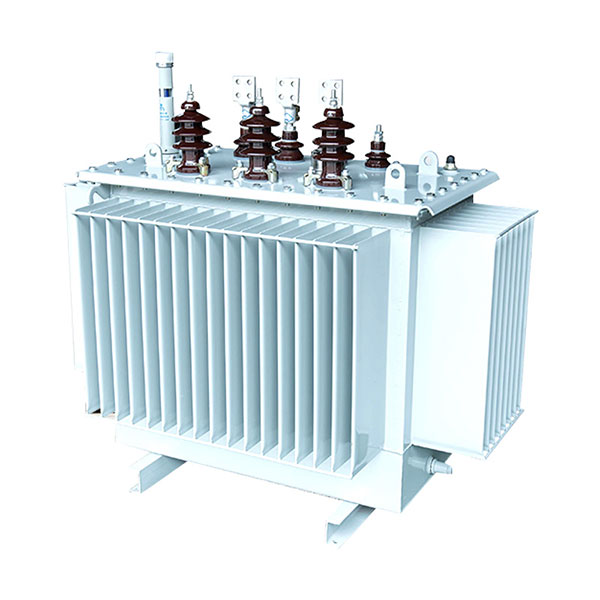

Power transformer S13

-

Complete low -voltage equipment GKK

-

Complete low-voltage equipment MNS 4000-6300A

-

GKG-12 high voltage

-

YBW-12 Prevented YBW-24 substation (European substation)

-

High voltage cable branch box

-

High voltage distribution cabinet KYN28-12

Distribution box for mining pdk

The PDK mining box is a type of equipment for the distribution of electricity, specially designed for special operating conditions, such as mines.

Description

marker

Structural characteristics

Shell material

1. Supporting it is made of a high -strength steel plate or stainless steel sheet, which have good resistance to compression, blows and corrosion. These materials withstand various external influences and chemical corrosion in the harsh conditions of the mine, and also ensure the safety of internal electrical components.

2. The surface of the case was subjected to special anti -corrosion treatment, such as the application of anti -corrosion paint, galvanizing, etc., to further increase its corrosion resistance.

Explosion -proof structure

1. To comply with the requirements of mine explosion protection, PDK distribution boxes, as a rule, have an explosion -proof structure. A non -resistant case can prevent the spread of flame and explosive products out of explosion inside, thereby preventing larger accidents.

2. The gaze and width of the fire -resistant connecting surface were strictly calculated and processed in such a way as to ensure the effective prevention of flame spread under pressure from the explosion. At the same time, the explosion -proof case is also equipped with a reliable sealing device that prevents the ingress of combustible gases and dust into the box.

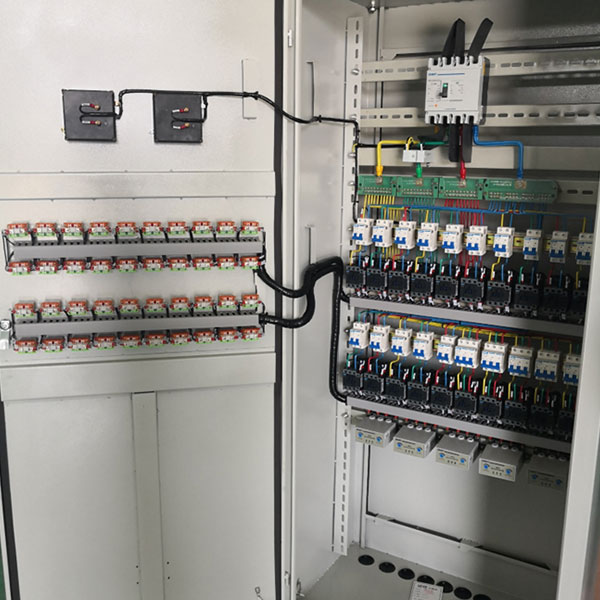

Internal layout

1. The reduced layout of the camshaft is reasonable and divided into various compartments, such as the main camera, the wires for connecting wires, etc. The main camera is used to install the main electrical components, such as automatic circuit breakers, contrivals and relay, and the installation chamber is used to connect incoming and outgoing cables.

2. The answer is isolated by explosion -proof partitions or metal partitions to ensure the independence and safety of electrical components. At the same time, the internal wiring is neat and standardized, and wire highways or wire pipes are used for laying, which are easy to maintain and overhaul.

Working mechanism

1. He is equipped with reliable control mechanisms, such as handles, buttons, etc., which are used to control the re -closing of the circuit breaker. The drive mechanism is simple in design, convenient in operation, has good mechanical properties and reliability.

2. The avoidance of improper operation of the drive mechanism is usually equipped with a blocking device, which can only work under certain conditions, which increases the safety of equipment.

Operational characteristics

Electric characteristics

1. The minor voltage is usually 660 V AC, 1140 V, etc., which can be selected in accordance with the actual needs of the mine. Nonomal current varies depending on various models and technical characteristics. The most common are 100a, 200A, 400A, etc.

2. He has a high ability to rupture during a short circuit and protection against overload and can quickly turn off the chain in case of short circuit or failure during overload to ensure the safety of electrical equipment and circuits.

3. The use of advanced electrical components and technologies, such as intellectual circuit breakers, multifunctional devices, etc., allowed to provide intellectual monitoring and energy system management.

Safety indicators

1. He was developed and manufactured in strict accordance with the relevant national standards and specifications and passed certification for explosion protection and safety tests to ensure safe and reliable operation in mine conditions.

2. He has perfect security measures, such as protection against overload, short circuit, leakage, grounding, etc. In the same time, there are warning signs and indicators that resemble operators about the need to observe safety precautions.

The effectiveness of protection

1. The protection of protection, as a rule, is IP54 or higher, which allows you to effectively prevent dust, water vapor and foreign objects into the body and ensure the normal operation of the electrical components.

2. He has good corrosion resistance and seismic resistance and can adapt to the harsh environmental conditions of the mines.